- CCC Polished Concrete Melbourne

sales@cccpolishedconcrete.com.au

Office: 1300 476 547

Showroom: 03 9761 5233

Showroom By Appointment (More Info)

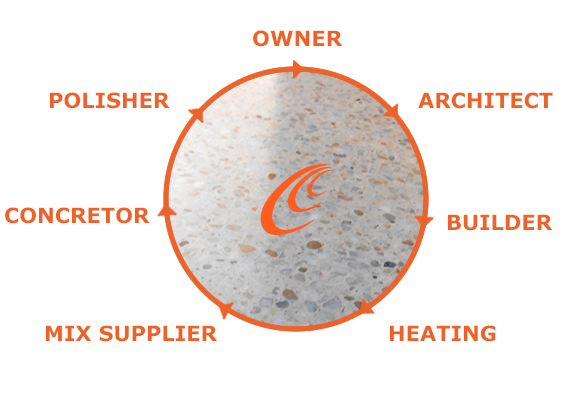

To achieve a quality polished concrete floor with exacting levels of exposure and finish required takes a high level of pre-preparation and communication between a number of contractors.

Whenever planning a new floor the Property Owner, Architect, Builder, Concrete Mix Supplier, Slab Concretor, Floor Polisher and where applicable the Hydronic Heating installer all need to communicate before the slab is poured.

The owner and/or architect initially need to decide on the desired concrete mix colour, the level of exposure, the type of finish to be achieved in the final floor and whether hydronic heating will be installed in the floor.

Once these decisions have been made the polished concrete floor circle of trust can be co-ordinated to facilitate a trouble free concrete pouring and polishing procedure and ensure a quality finish that meets the original expectations.

It is critical that pre-preperation is completed well in advance of slab pouring as it can be expensive to make changes to a job after the fact particularly if something has gone awry because of issues with the concrete mix or the method of pouring and trowelling the slab etc.

To help owners, architects and concrete contractors do their homework we have established our polished concrete showroom where our experienced staff can explain pre-preparation requirements anout outline the differences between concrete floors.

Visitors to our showroom can view finished polished concrete surfaces from various aggregate and coloured concrete mixes. If requested we can also suggest experienced slab and heating contractors and mix suppliers to help with the initial set up of the polished concrete floor circle of trust to ensure that everything runs smoothly.

We can also offer advice to contractors, builders and architects before pouring in how to best prepare a slab suitable for concrete polishing.

As proponents of the wonder of polished concrete we have also poured much information into this website and will continue to build the knowledgebase so that polished concrete floor projects can be improved across the industry.

Visit the CCC Polished Concrete Showroom

18/51-55 Centre Way, Croydon South

Monday to Friday 8am to 5pm.

Saturday (and A/H) by appointment only.

Phone: 03 9761 5233 or email This email address is being protected from spambots. You need JavaScript enabled to view it.

Site information to assist builders with timing schedules and CCC Polished Concrete requirements.

Please read in conjunction with our terms and conditions.

CCC On Site Information Document

CCC Terms and Conditions

Please be aware that CCC Polished Concrete work on the surface of your concrete slab. The end result, durability and longevity of polished concrete has much to do with the quality of the concrete and the methods used by your concretor and builder in pouring and finishing the slab.

Please be sure to use a professional builder and concreter who will follow the correct procedures for preparing, pouring and most importantly trowelling a slab if intended for a polished concrete finish.

CCC Polished Concrete is happy to liaise with your concreter before they pour to help avoid common mistakes.

Phone Rick BEFORE you POUR on 0418 553 982

Our objective here at CCC Polished Concrete is to leave you with a finished floor that requires little ongoing maintenance.

Please download a maintenance sheet that correspondence with your floor finish type to help you keep your floor surface clean and trouble free.

Maintenance Sheets

The better the slab the better the finish that we can achieve.

Please make sure to use a professional concreter and emphasise the requirements that will achieve the type of finish you require.

CCC Polished Concrete is happy to liase with your concreter before they pour, for example, it is important that retarding agents are NOT added to a concrete mix that is going to be either ground and sealed or polished! Retarding agents WILL affect the seal and may react badly with the polishing process. Simply apply a light sprinkle of water to the slab as required.

Phone Rick BEFORE you POUR on 0418 553 982

- Download our CONCRETE PROCEDURE tip sheet for concreters

- Download placement guidelines document

- An example of how to do boxing properly

Lawrence hard at work at the CCC showroom.

|

CCC Polished Concrete uses the highest quality polishing pads and grinding heads as supplied by Grinding Tools Australia (GTA) We use the latest state of the art concrete grinding and polishing equipment to ensure our floor finishes are of the highest quality. The PG 820 is the largest in the range of surface preparation and finishing machines. Equipped with Dual Drive Technology™ the PG 820 is among the market’s most powerful and efficent machines.

|

|

Over 5000 years ago the Egyptians were using early forms of concrete to build pyramids.

The ancient Romans (4700 years later) used a material remarkably close to modern concrete to build many architectural marvels such as the Colesseum and Pantheon.

Back as far as 9000BC the first decorative form of concrete “terrazzo” was used in Neolithic buildings in Western Asia. Goats milk and bees wax were used as sealers to protect and add lustre.

The process of polishing concrete became far less labour intense with the development of grinding machinery and sophisticated sealers and indensifiers (hardeners).

The industry is now virtually able to offer any finish that architects, designers and home-owners desire.

It is not surprising that one of the strongest materials known to man has now become his favoured choice of flooring, for not only its beauty, but strength and durability.

MAINTENANCE FOR OUR CCC POLISHED CONCRETE FINISH

CCC Polished Concrete is a coating free system with the objective of providing a finished floor with little ongoing maintenance.

Your floor should be maintained on a regular basis by vacuuming and cleaning in the following manner: To bucket of warm water, add recommended amount of Tough Green Cleaner (or neutral ph cleaner), and mop floor with a microfibre mop. The floor should be damp for the shortest time possible. This will leave the floor clean & streak free. This simple cleaning should be carried out as required to keep the floor looking its best.

Avoid cleaning with any other products as this may cause rejection of coating when maintenance is required.

CAUTION: Concrete floors may be slippery, particularly when wet, please take care as no responsibility is accepted. Do not use any buffing type machine or product or any type of abrasive cleaner as this will dull the surface.

PERIODICAL MAINTENANCE

Low Traffic Areas / Residential

- Depending on the surrounding environment these areas will require a burnish using a high speed burnisher with Red Nylon Pads only when deemed necessary.

High Traffic Areas / Commercial

- Burnish on a regular basis with a high speed burnisher using Red Nylon Pads to maintain a high gloss and or dust free surface.

Caution: Do not use any Bleach Based or Citrus Based Cleaners

Simple Tips:

- Fit protective pads to chairs & tables.

- Castor legs should be fitted into castor cups.

- Use a dry Microfibre Mop regularly.

- Avoid direct heat from free standing heaters.

- Spills should be cleaned up straight away to avoid penetration or damage.

CCC Polished Concrete Finishes

Level of grinding and final finishes. How much stone should be visible & how durable should a floor be?